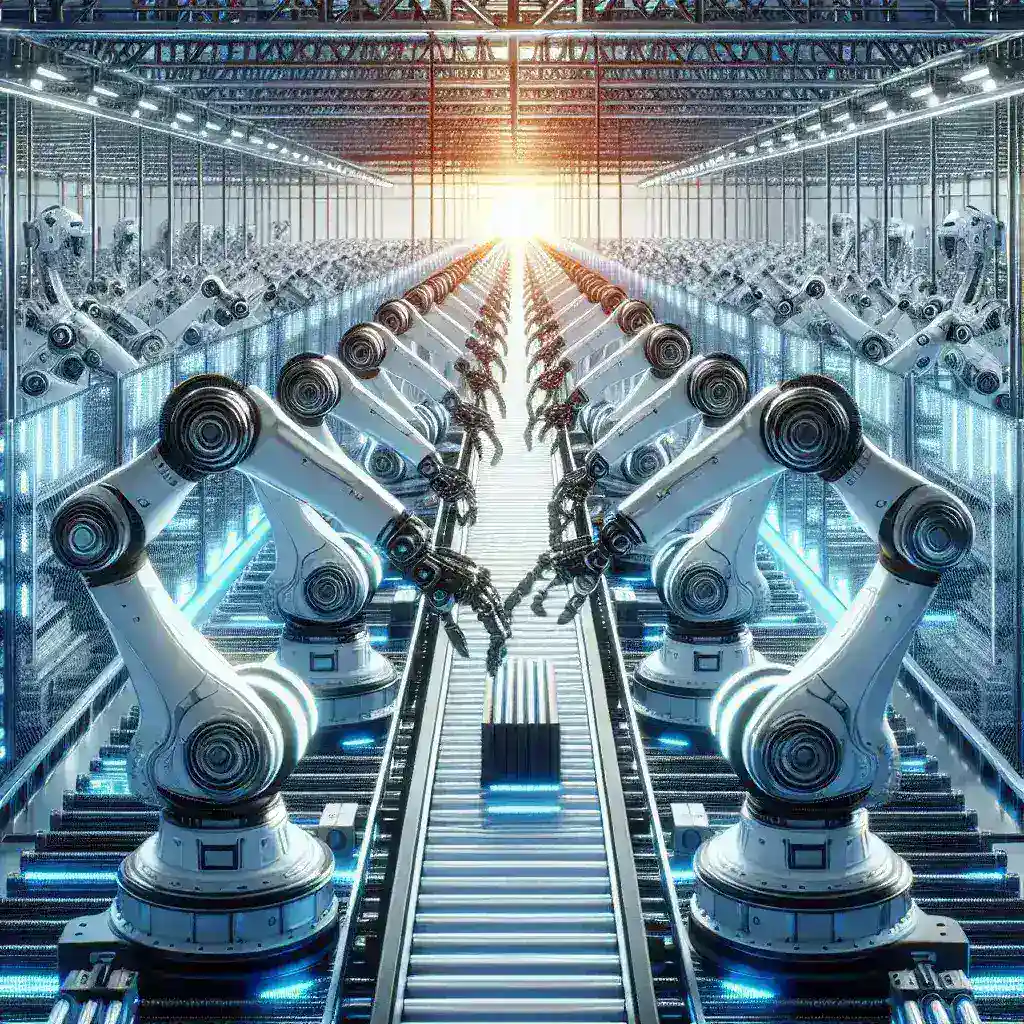

The landscape of warehouse automation is undergoing a profound transformation as robotics firms race to develop solutions that mimic human-like dexterity. With the growing demands of e-commerce and supply chain efficiency, these companies are leveraging advanced technologies to create robots capable of performing intricate tasks traditionally reserved for human workers. This article delves into the current innovations, the challenges faced, and the implications of achieving human-like dexterity in warehouse automation.

Understanding the Challenge of Dexterity

Dexterity in robotic systems refers to the ability to perform complex movements with precision and adaptability. Traditional automation solutions often rely on rigid machinery that can execute repetitive tasks efficiently but struggle with the flexibility needed for more intricate operations. As warehouses evolve into dynamic environments where the nature of the work can change rapidly, the need for dexterous robots has never been more crucial.

Historical Context

The journey toward dexterous robotics began in the late 20th century with simple robotic arms designed for assembly lines. These systems excelled in speed and accuracy but lacked the finesse required for tasks like picking and placing items of varying shapes and sizes. As technology advanced, so too did the capabilities of these machines, leading to the development of more sophisticated robots equipped with sensors, artificial intelligence, and machine learning algorithms.

The Evolution of Robotics in Warehousing

- Early Automation: Initial efforts focused on conveyor belts and robotic arms that could automate repetitive tasks.

- AI and Machine Learning: The introduction of AI allowed robots to learn from their environment, improving their adaptability.

- Sensory Technology: Robots began to utilize cameras and sensors to enhance their perception, enabling them to navigate complex environments.

Current Innovations in Robotics

Today, robotics firms are at the forefront of innovation, introducing solutions that significantly enhance dexterity. Some of the key advancements include:

1. Advanced Gripping Mechanisms

Modern robots are equipped with sophisticated grippers that can adapt to various object shapes and sizes. These grippers often mimic the human hand’s ability to grasp and manipulate items delicately. For example, soft robotics technologies utilize flexible materials that allow robots to handle fragile products without damage.

2. Enhanced Sensory Feedback

Robots now incorporate advanced sensors that provide real-time feedback about their environment. This capability allows them to adjust their movements on-the-fly, significantly improving accuracy and efficiency in tasks like picking and sorting.

3. AI-Powered Decision Making

Artificial intelligence plays a pivotal role in enhancing robotic dexterity. Algorithms analyze vast amounts of data, helping robots make informed decisions about how to approach tasks. This intelligence enables them to adapt to new challenges, such as working alongside human employees.

Challenges in Achieving Human-Like Dexterity

Despite the remarkable progress, several challenges remain in developing robots with human-like dexterity:

1. Complexity of Human Movements

Replicating the intricate movements of the human hand is no easy feat. The human hand’s ability to perform precise, multi-fingered tasks requires a level of coordination that is challenging to achieve in robotic systems.

2. Cost of Development

Developing advanced robotic systems is expensive. Firms must invest significant resources into research, development, and testing to create solutions that meet the demands of warehouse automation.

3. Integration with Existing Systems

Many warehouses still rely on traditional automation methods. Integrating new, dexterous robots into these existing systems can be complex and requires careful planning and execution.

Future Predictions for Robotics in Warehousing

The future of robotics in warehouse automation is promising. As technology continues to advance, we can expect:

1. Increased Automation

As companies seek to improve efficiency and reduce labor costs, the adoption of dexterous robots will likely increase, leading to fully automated warehouses.

2. Collaboration with Human Workers

Rather than replacing human employees, robots will increasingly work alongside them, enhancing productivity and creating safer work environments.

3. Customization and Flexibility

Future robots will be designed to rapidly adapt to different tasks and environments, making them more versatile and valuable in diverse warehouse settings.

Real-World Examples

Several companies are leading the charge in developing dexterous robotic solutions:

1. Boston Dynamics

Known for their advanced robotics, Boston Dynamics has developed robots like Stretch, a robotic arm designed for warehouse tasks, showcasing remarkable dexterity and adaptability.

2. Amazon Robotics

Amazon’s acquisition of Kiva Systems revolutionized their warehouse operations. Their robots are equipped with sensors and AI capabilities, enabling them to navigate complex environments efficiently.

3. Collaborative Robots (Cobots)

Firms like Universal Robots focus on creating cobots that work alongside human workers, enhancing productivity without replacing the human touch.

Conclusion

The race towards human-like dexterity in warehouse automation is not just a technological challenge; it represents a paradigm shift in how we view labor and efficiency in supply chains. As robotics firms continue to innovate and overcome the hurdles in achieving dexterous capabilities, the future promises a new era of automation that balances human skill with robotic precision. The implications for productivity, safety, and job dynamics in warehouses will be profound, making this an exciting field to watch as it evolves.

Leave a Reply